Originally Posted by

planters

John,

The difference with the matched bushings is that the high precision thread cutting machine that makes the screw also makes the bushing. Your general purpose thread tap (God forbid hand tap) will not give the same creamy feel. The bushings come with either a press fit or an outer, coarser thread. You can also get even more extreme threads up to 200/inch for not much more cost. There was a small precision tool maker presenting @ last year's Photonics West Expo that sold a nice variety of these. I'll look and see if I can find the name of the company. You can still tap your holes (the way I've done it) and thread the bushing in TIGHT. It wont move then even if you had cut a loose thread fit

you can probably get those in China for 5 bucks - haha seriously - just trying to lighten things up...But really...you two should get a room so you can discuss the difference between apples and oranges, whether US or Chinese because this thread is about piss easy cheap laserman532 micro mounts.

see I can have a sense of humor under the most adverse conditions...

Pat B

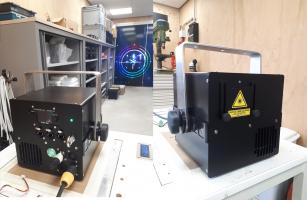

laserman532 on ebay

Been there, done that, got the t-shirt & selling it in a garage sale.

Reply With Quote

Reply With Quote