Small taps aren't that strong I've found so a nice slow and controlled speed worked well for me

At 800rpm it taps 16 holes 10mm deep in 2mins flat

Eat Sleep Lase Repeat

Tapping speed is mostly going to be determined by how much coolant you have in the hole. Tapping at anything over 1k RPM is ill-advised unless you have liquid flood coolant. Simply putting a little oil in the holes before you start the tapping cycle will only get you so far.

The annoying thing about tapping heads is if you're using a cutting tap ('regular' style tap) you can't do chip break cycles, so tapping long holes isn't advised. There are two types of taps that will get more efficiency out of your tapping head: one is a standard cut tap that has small channels cut into the flutes which break the chips once they reach a certain length, which helps chip evacuation out of the hole and ensures you never have chips longer than a certain length. You can even grind your own flute reliefs if you have a diamond wheel. The second is form taps. Instead of cutting material away, they deform the material along the hole wall into threads (NOTE: you need to drill a larger diameter hole for form taps. They come with their own tap drill size chart). They not only make stronger, more rigid threads (which is good for lenses since they'll fit tighter), but you can tap much faster with them with less chance of binding (and breaking) the tap on a stray chip. We routinely form tap 0-80 holes at 5k RPM here in my shop, but we have flood coolant.

Cheers!

Neat!

I have coolant flood but I don't use it when tapping, I put lots if oil in each hole. Nit had any issues, also I use a spiral flute tap

Eat Sleep Lase Repeat

That's pretty much how I do it. No power though, I just run the drive belt by hand, the inertia in the system makes it run smooth. I always use a fluteless tap. I think they're chrome vanadium with some kind of 'flashing' on them to make a hard surface. They need exact drill sizes prior, and even that varies according to depth or choice of metal but it works for me. It cold-forms the thread so it's tough, and very finely surfaced. I have one 3mm tap, and one 4mm tap. I have never needed another size in the 20 years I have done this (it helps that most stuff I do is small enough not to need it), and I have never broken a tap.

I've never had a CNC mill but if they can have enough control of vertical position changing as the thread is formed, this could be fast. As it is, I can sink a 3mm thread to 16 mm in a few seconds with no risk, I just have to not do it if I'm tired and stupid.. The method works well in aluminium of any grade I've tried, and in brass and copper and mild steel and acetal plastic. Stainless steel too, just slower to do. I use a drip of 3-in-1 oil if the hole is deeper than 5mm, especially if it's a blind hole.

I use flood for cutting Just not tapping

Eat Sleep Lase Repeat

One thing I forgot to mention with setting the z, if your hole is 10mm deep when using the tapmatic don't goo to 10mm. On mine once the z stops going down and starts going back up the tap travels a further 3mm. The clutch needs to engage and change to reverse

Eat Sleep Lase Repeat

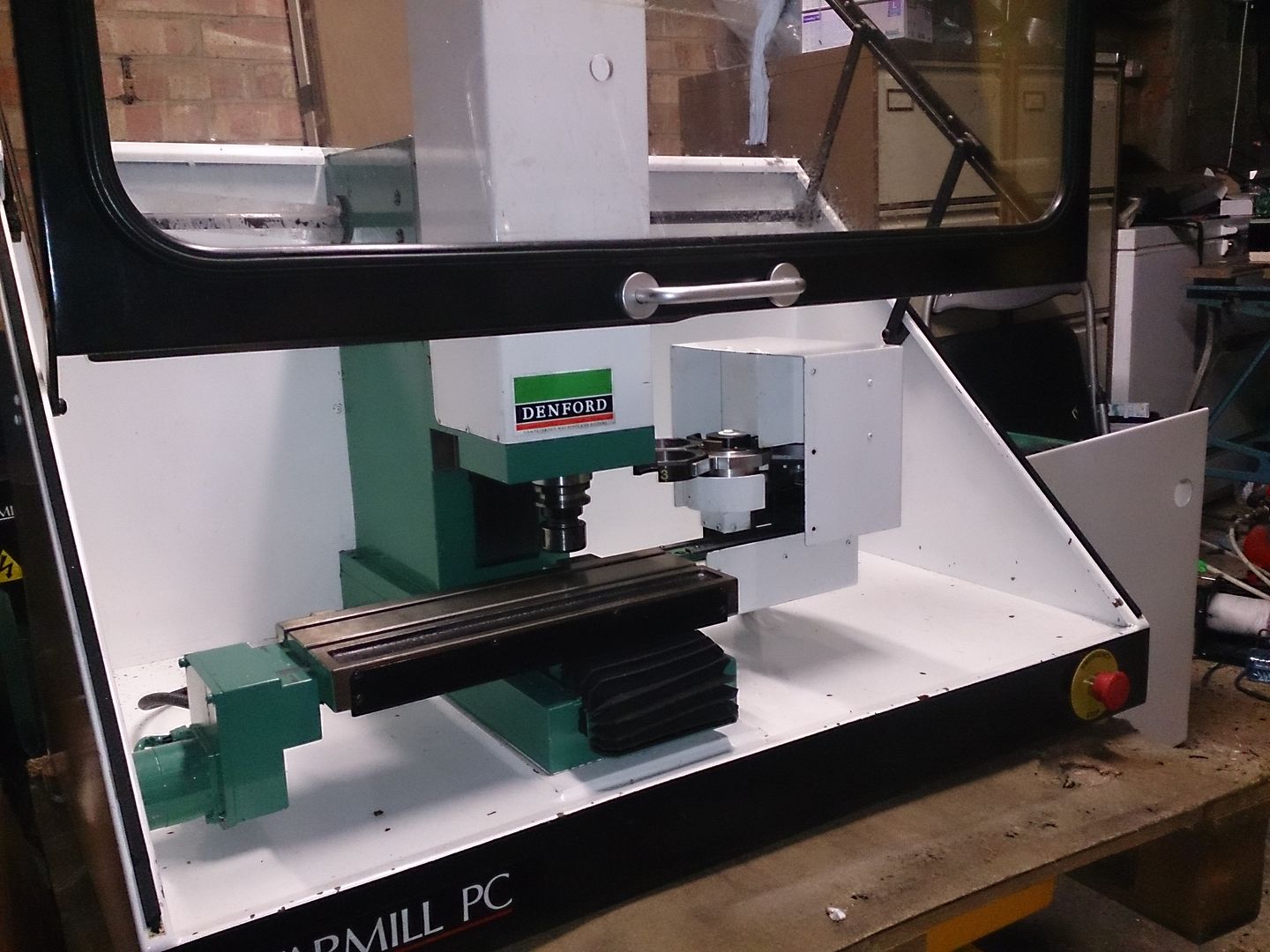

New toy collected today starmill with three station tool changer

Eat Sleep Lase Repeat

Looks like a short HeNe tube holder to me.